- Blog

Optimization: Rotor Blade Sorting for Jet Engines

Dr. Avigail Kaner

May 2, 2024

In this blog post we demonstrate how we optimized rotor blade sorting for an aerospace manufacturer using a QUBO formulation running on the LightSolver platform and benchmarking the results against Gurobi 10.0.2

Rotor balancing is a well-known challenge in turbine manufacturing and maintenance [1] [2]. Rotors are composed of tens of fan blades with each differing slightly in weight when manufactured and even more so after the accumulation of milage. When running at full speed, with thousands of rotations per minute, even the slightest unbalance causes a deviation in the mass center and consecutively undesired engine vibrations. Hence, before assembly, all rotor blades are weighed and the best sorting is determined, so that the rotor is optimally balanced. Similarly, during maintenance, rotors are completely disassembled, inspected and re-assembled, with the optimal sequence needing to be established again according to the actual weight of each blade.

With a super-exponential number of possible placement combinations, blade sorting is a complex combinatorial optimization challenge that requires substantial computation power and time to achieve accurate solutions, even for a moderate number of blades. Commonly used heuristics methods limit the search space and often don’t produce accurate results, even more so within the tight timeframe that is required to guarantee an uninterrupted workflow in assembly and maintenance centers. Improved optimization solutions are needed that enable aerospace manufacturers and maintenance providers to maximize operational processes while improving outcomes, helping to avoid gradual wear, costly repairs, and dangerous incidents.

Skip the mathematics and go directly to the results

Skip the mathematics and go directly to the results

MATHEMATICAL DEFINITION

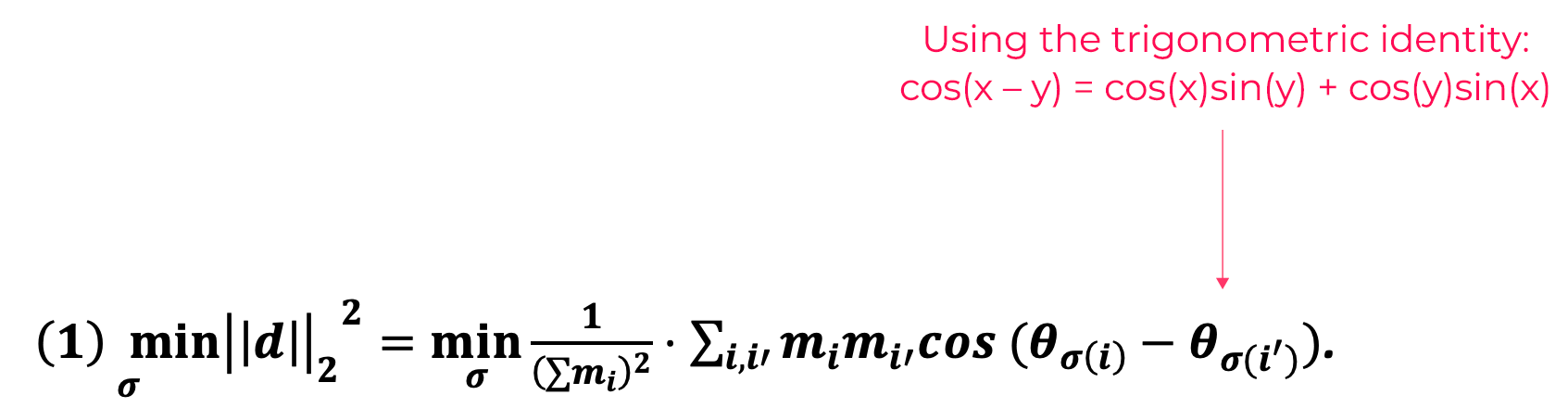

The objective is to find an assignment, σ, which minimizes the (squared) length of the unbalance vector:

QUBO FORMULATION

We define binary variables , which correspond to positioning the ith blade at angle .

resulting in:

Combining the penalty and the objective term gives the QUBO formulation for the blade sorting problem:

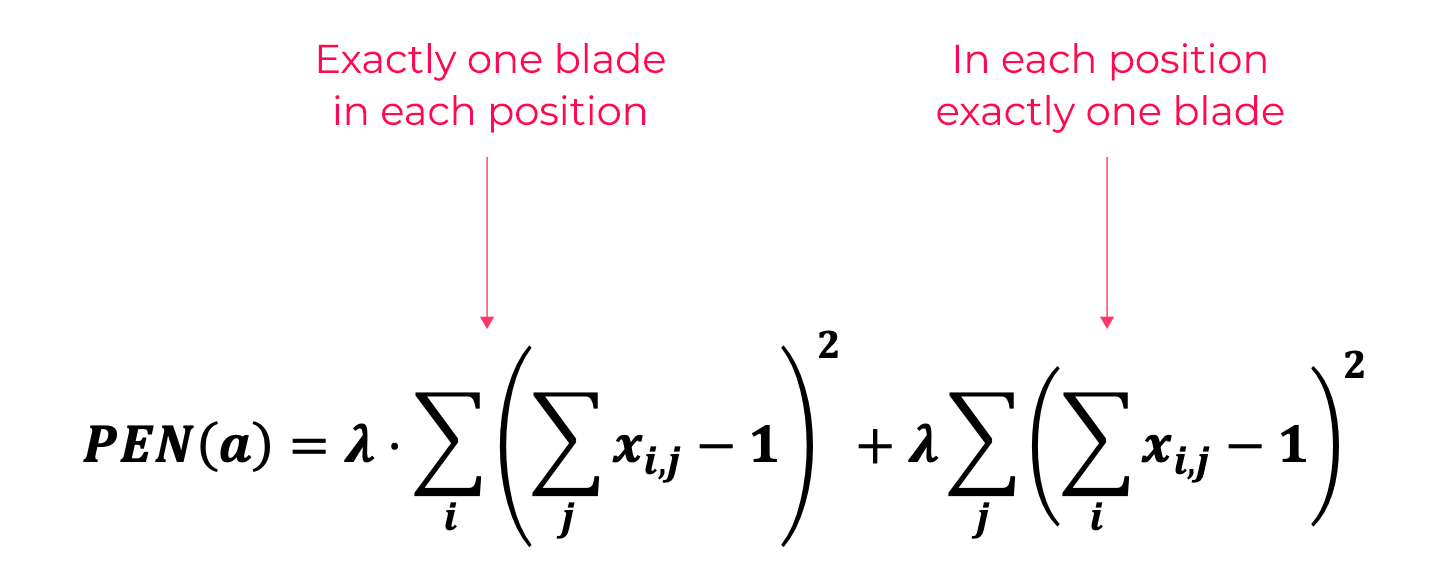

With the complexity of the problem increasing exponentially with each additional blade, we decided to challenge and evaluate the performance of the LightSolver solution for rotors of up to 80 fan blades. To reflect the constraints of busy assembly teams, we selected runtimes of 60 and 600 seconds, optimizing for minimal unbalance, expressed by the length of the unbalance vector (y axis).

As the graphs show, our formulation proved highly efficient, and when running on the quantum-inspired LightSolver platform it consistently produced solutions of superior quality for all problem sizes (number of fan blades), expressed by a minimal unbalance vector length, outperforming Gurobi. Equally important from an operational perspective, LightSolver managed to deliver high-quality solutions for runtimes as short as one minute and even for the largest rotor with 80 blades, when the Gurobi solver failed to calculate solutions for instances above 50 blades.

Fan blade sorting for rotor assembly has been a long-standing challenge addressed by researchers and software providers. As with most complex optimization problems, professionals had to compromise either on solution accuracy or timelines. With LightSolver’s quantum-inspired platform, organizations can now get the best of both worlds, for optimal efficiency and – in the case of rotor blade sorting – utmost safety.

For more information on the LightSolver platform, contact us at info@lightsolver.com.

About the author

Dr. Avigail Kaner

Dr. Avigail Kaner is an Algorithm Researcher at LightSolver and combines experience in theoretical and practical research. Avigail earned her PhD in Physics from the Hebrew University of Jerusalem where she contributed to multi-disciplinary studies spanning physics, biology, and economics. Avigail likes to spend time outdoors and go on hikes with her family.

Altug Piskin, Himmet Emre Aktas, Ahmet Topal, Onder Turan, Tolga Baklacioglu, "Rotor Balancing with Turbine Blade Assembly Using Ant Colony Optimization for Aero-Engine Applications", International Journal of Turbo & Jet-Engines, Volume 38 Issue 2, 2017

Chuanzhi Sun, Pinghuan Xiao, Xiaoming Wang, Yongmeng Liu, "Blade Sorting Method for Unbalance Minimization of an Aeroengine Concentric Rotor", Symmetry 2021, 13, 832

Sign up for updates

Get news and blog posts straight to your inbox!

LightSolver Ltd., its parent company and its affiliates (“LightSolver”, “we”, “our” or “us”) welcome you to our website at https://lightsolver.com/ (the “Site”).Our Site offers basic information on our company and technology. These Website Terms of Use (these “Terms”) govern your access to and use of the Site.

All references to “you”or “User,” as applicable, mean the person who enters, connects to, accesses, or uses the Site in any manner, and each of your heirs, assigns, and successors. If you use the Site on behalf of an entity, you represent and warrant that you have the authority to bind that entity, your acceptance of these Terms will be deemed an acceptance by that entity, and “you” and “your”herein shall refer to that entity, its directors, officers, employees, and agents.

BY ENTERING, CONNECTING TO,ACCESSING AND/OR USING THE SITE, YOU ACKNOWLEDGE THAT YOU HAVE READ AND UNDERSTOOD THESE TERMS, AND YOU AGREE TO BE BOUND BY THEM AND TO COMPLY WITH ALL APPLICABLE LAWS AND REGULATIONS REGARDING YOUR USE OF THE SITE. YOU ACKNOWLEDGE THAT THESE TERMS CONSTITUTE A BINDING AND ENFORCEABLE LEGAL CONTRACT BETWEEN LIGHSOLVER AND YOU. . IF YOU DO NOT AGREE TO THESE TERMS, PLEASE DO NOT ENTER, CONNECT, ACCESS OR USETHE SITE IN ANY MANNER.

The Site includes informative pages on our product(s) and service(s), as well as our company. In addition, there are forms that Users may fill in, which include, without limitation: (i)“Contact Us” form; (ii) “Demo Request Form”; (iii) “About Us” – enabling Users to learn more about us; (v) “Solutions”– enabling Users to learn about LightSolver’s technology, products and services; and (vi) “Careers” – enabling potential candidates to apply for job opportunities at LightSolver. To learn more about the information you provide us when filling in one or more of the forms, please review our to apply for job opportunities at LightSolver. To learn more about the information you provide us when filling in one or more of the forms, please review our Website PrivacyPolicy at(“PrivacyPolicy”).

There is certain conduct which is strictly prohibited on the Site. Please read the following restrictions carefully. Your failure to comply with the provisions set forth below may, at LightSolver’s sole discretion, result in the termination of your access to the Site and may also expose you to civil and/ or criminal liability.

You will not, and you will not direct any third parties to: (i) copy, scrape, modify, create derivative works of, adapt, emulate, translate, reverse engineer, compile, decompile or disassemble any portion of the content on theSite and any other information, documents, material and data available on theSite (collectively, the “Content”)in any way, or publicly display, perform, or distribute the Content, without LightSolver’s prior written consent; (ii) make any use of the Content on any other website or networked computer environment for any purpose, or replicate or copy theContent without LightSolver’s prior written consent; (iii) create a browser or border environment around theSite and/or Content, link, including in-line linking, to elements on the Site, such as images, posters and videos, and/or frame or mirror any part of theSite; (iv) transmit, distribute, display or otherwise make available through orin connection with the Site any content which may infringe third party rights, including intellectual property rights and privacy rights, or which may contain any unlawful content; (v) transmit or otherwise make available in connection with the Site, and/or use the Site to distribute and/or otherwise transmit any virus, worm, trojan horse, time bomb, web bug, spyware, or any other computer code, file, or program that mayor is intended to damage or hijack the operation of any hardware, software, or telecommunications equipment, or any other actually or potentially harmful, disruptive, or invasive code or component; (vi) interfere with or disrupt the operation of the Site, or the servers or networks that host the Site or make the Site available, or disobey any requirements, procedures, policies, or regulations of such servers or networks; or (vii) use the Content and/or theSite for any illegal, immoral or unauthorized purpose.

We respect the privacy of ourUsers and are committed to protecting the information you share with us in connection with your use of the Site. Our policy and practices and the type of information collected are described in our PrivacyPolicy[H.A.1] , which is incorporated herein by reference. By connecting to, accessing or using the Site, you acknowledge that you have read and agree to the Privacy Policy.

LightSolver grants you a limited, personal, non-exclusive, non-assignable, not-tradeable, non-sub-licensable, fully and immediately revocable at LightSolver’s discretion, license, to use the Site and reproduce and display any Content made available for download and downloaded by you from the Site (the “Materials”), solely for your personal and non-commercial use, all subject to the terms and conditions in these Terms. These Terms do not entitle you with any right in the Site or in the Content or Materials, rather only to a limited right to use the same it in accordance herewith.

The Materials are made available to you subject to the terms of Section 3 above, for your own personal limited use, and without derogating from the restrictions set forth under theseTerms and in addition thereto, you may not: (i) distribute the Materials or any part thereof, directly or indirectly; (ii) make or allow any third party to make any commercial use of the Materials; and (iii) modify, add, subtract, aggregate or otherwise make any derivative work of the Materials or allow a third party to do so.You hereby agree that uponCompany’s request you will immediately return all Materials, purge your systems from any Materials and ensure that no copies, extracts or other reproductions are retained by you.

In the event that you provide LightSolver with any suggestions, comments or other feedback relating to Site and/or LightSolver products and/or services (collectively, “Feedback”),such Feedback is deemed as the sole and exclusive property of LightSolver and you hereby irrevocably assign to LightSolver all of its rights, title and interest in and to all Feedback, if any, and waive any moral rights to it (or anyone on your behalf) may have in such Feedback. By sending us any Feedback, you hereby represent and warrant that (a) you have the right to disclose the Feedback, (b)the Feedback does not violate the rights of any other individual or entity, and(c) your Feedback does not contain the confidential or proprietary information of any third party. By sending us any Feedback, you further (i) agree that we are under no obligation of confidentiality, express or implied, with respect to the Feedback and (ii) acknowledge that we may have something similar to theFeedback already under consideration or in development. You shall promptly inform LightSolver as soon as you become aware of any third party right or imitation which may apply to Feedback already provided. This Section 6 shall survive any termination of your access to the Site or any of our products or services.

“LightSolver Intellectual Property” means any and all proprietary and intellectual property rights, including the Site, its logos, graphics, icons, images, as well as the selection, assembly and arrangement thereof, LightSolver’s proprietary software, algorithms and any and all intellectual property rights pertaining thereto, including, without limitation, inventions, patents and patent applications, trademarks, trade names, logos, copyrightable materials, graphics, text, images, designs (including the “look and feel” of the Site and any part thereof), specifications, methods, procedures, information, know-how, data, technical data, interactive features, source and object code, files, interface and trade secrets, whether or not registered and/or capable of being registered, and any and all Feedback.

The LightSolver Intellectual Property is owned by and/or licensed to LightSolver and is subject to copyright and other applicable intellectual property rights under local laws, foreign laws and international conventions. You may not copy, distribute, display, execute publicly, make available to the public, emulate, reduce to human readable form, decompile, disassemble, adapt, sublicense, make any commercial use, sell, rent, lend, process, compile, reverse engineer, combine with other software, translate, modify or create derivative works of any material that is subject to LightSolver’s proprietary rights, including the LightSolver Intellectual Property, either by yourself or by anyone on your behalf, in any way or by any means, unless expressly permitted in these Terms.

“LightSolver” and all logos and other proprietary identifiers used by LightSolver in connection with the Site (“LightSolver Trademarks”), are all trademarks and/or trade names of LightSolver, whether or not registered. All other trademarks, Site marks, trade names and logos which may appear on or with respect to the Site belong to their respective owners (“Third Party Marks”).No right, license, or interest to LightSolver Trademarks and/or to the Third Party Marks is granted hereunder, and you agree that no such right, license, or interest shall be asserted by you with respect to LightSolver Trademarks or the Third Party Marks and therefore you will avoid using any of those marks, unless expressly permitted herein. You are hereby prohibited from removing or deleting any and all copyright notices, restrictions and signs indicating proprietary rights of LightSolver and/or its licensors, including copyright mark © or trademark ® or ™ contained in or accompanying the Site, and you represent and warrant that you will abide by all applicable laws in this respect. You are further prohibited from using, diluting or staining any name, mark or logo that is identical, or confusingly similar to any of LightSolver’s marks and logos, whether registered or not.

No licenses or rights are granted to you by implication or otherwise under any LightSolver Intellectual Property, except for the licenses and rights expressly granted in these Terms.

The Site may use or include third party software, files and components that are subject to open source and third party license terms (“Third PartyComponents”). Your right to use such Third Party Components as part of, orin connection with, the Site is subject to any applicable acknowledgements and license terms accompanying such Third Party Components, contained therein or related thereto. These Terms do not apply to any Third Party Components accompanying or contained in the Site, and LightSolver disclaims all liability related thereto. You acknowledge that LightSolver is not the author, owner or licensor of any Third Party Components, and that LightSolver makes no warranties or representations, express or implied, as to the quality, capabilities, operations, performance or suitability of Third Party Components.Under no circumstances shall the Site or any portion thereof (except for theThird Party Components contained therein) be deemed to be “open source” or“publicly available” software.

The Site’s availability and functionality depend on various factors, such as communication networks, software, hardware, and LightSolver’sSite providers and contractors. LightSolver does not warrant or guarantee that the Site will operate and/ or be available at all times without disruption or interruption, or that it will be immune from unauthorized access or error-free.

LightSolver reserves the right, at its sole discretion, to modify, correct, amend, enhance, improve, make any other changes to, or discontinue, temporarily or permanently, the Site(or any part thereof) without notice, at any time. In addition, you hereby acknowledge that the Content available through the Site may be changed, modified, edited or extended in terms of content and form or removed at anytime without any notice to you. You agree that LightSolver shall not be liable to you or to any third party for any modification, suspension, error, malfunction or discontinuance of the Site (or any part thereof).

LIGHTSOLVER DOES NOT WARRANT ORMAKE ANY REPRESENTATIONS REGARDING THE USE, THE INABILITY TO USE OR OPERATE, ORTHE RESULTS OF THE USE OR OPERATION OF THE SITE (OR ANY PART THEREOF). LIGHTSOLVER SHALL NOT BE LIABLE FOR ANY DAMAGES WHATSOEVER, INCLUDING, BUT NOT LIMITED TO,DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY KIND,WHETHER IT WAS CAUSED CONSEQUENTLY OR IN CONNECTION WITH THE USE OF THE SITE,WHETHER OR NOT LIGHTSOLVER HAD INFORMED THE USER OF SUCH POSSIBLE DAMAGE.

THE SITE (AND ANY PART THEREOF), INCLUDING WITHOUT LIMITATION ANY CONTENT, DATA AND INFORMATION RELATED THERETO, ARE PROVIDED ON AN “AS IS” AND “AS AVAILABLE” BASIS, WITHOUT ANY WARRANTIES OF ANY KIND, EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF TITLE OR NON-INFRINGEMENT OR IMPLIED WARRANTIES OF USE, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR USE. LIGHTSOLVER DISCLAIMS AND MAKES NORE PRESENTATIONS OR WARRANTIES AS TO THE ACCURACY, QUALITY, AVAILABILITY,RELIABILITY, SUITABILITY, COMPLETENESS, TRUTHFULNESS, USEFULNESS, OR EFFECTIVENESS OF ANY CONTENT AVAILABLE ON OUR SERVICES. LIGHTSOLVER AND ANY OF ITS OFFICERS, DIRECTORS, SHAREHOLDERS, EMPLOYEES, SUB-CONTRACTORS, SERVICE PROVIDERS, AGENTS AND OTHER AFFILIATED ENTITIES (COLLECTIVELY, “LIGHTSOLVER PARTIES”),JOINTLY AND SEVERALLY, DISCLAIM AND MAKE NO REPRESENTATIONS OR WARRANTIES AS TOTHE USABILITY, ACCURACY, QUALITY, AVAILABILITY, RELIABILITY, SUITABILITY,COMPLETENESS, TRUTHFULNESS, USEFULNESS, OR EFFECTIVENESS OF ANY CONTENT, DATA,RESULTS, OR OTHER INFORMATION OBTAINED OR GENERATED IN CONNECTION WITH YOUR ORANY USER’S USE OF THE SITE. LIGHTSOLVER DOES NOT WARRANT THAT THE OPERATION OFTHE SITE IS OR WILL BE SECURE, ACCURATE, COMPLETE, UNINTERRUPTED, WITHOUT ERROR, OR FREE OF VIRUSES, WORMS, OTHER HARMFUL COMPONENTS, OR OTHER PROGRAM LIMITATIONS. LIGHTSOLVER MAY, AT ITS SOLE DISCRETION AND WITHOUT AN OBLIGATION TO DO SO, CORRECT, MODIFY, AMEND, ENHANCE, IMPROVE AND MAKE ANY OTHER CHANGES TO THE SITE AT ANY TIME, OR DISCONTINUE DISPLAYING OR PROVIDING ANY CONTENT OR FEATURES WITHOUT ANY NOTICE TO YOU. YOU AGREE AND ACKNOWLEDGE THAT THE USE OFTHE SITE, INCLUDING USE OF AND/OR RELIANCE ON ANY CONTENT AVAILABLE THROUGH THE SITE, IS ENTIRELY, OR OTHERWISE TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, AT YOUR OWN RISK.

YOU ACKNOWLEDGE AND AGREE THAT, TO THE MAXIMUM EXTENT PERMITTED BY LAW, THE ENTIRE RISK ARISING OUT OFYOUR ACCESS TO AND USE OF THE SITE REMAINS WITH YOU. IN NO EVENT SHALL LIGHTSOLVER AND/OR ANY OF THE LIGHTSOLVER PARTIES BE LIABLE FORANY DAMAGES WHATSOEVER, INCLUDING DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY KIND, RESULTING FROM OR ARISING OUT OF THE SITE,USE OR INABILITY TO USE THE SITE, FAILURE OF THE SITE TO PERFORM AS REPRESENTED OR EXPECTED, LOSS OF GOODWILL, DATA OR PROFITS, THE PERFORMANCE OR FAILURE OF LIGHTSOLVER TO PERFORM UNDER THESE TERMS, AND ANY OTHER ACT OR OMISSION OF LIGHTSOLVER BY ANY OTHER CAUSE WHATSOEVER, INCLUDING WITHOUT LIMITATION DAMAGES ARISING FROM THE CONDUCT OF ANY USERS AND/OR THIRD PARTY SITES.

NO ACTION MAY BE BROUGHT BY YOUFOR ANY BREACH OF THESE TERMS MORE THAN ONE (1) YEAR AFTER THE ACCRUAL OF SUCH CAUSE OF ACTION. AS SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, THEN SUCH LIMITATIONS ONLY MAY NOT APPLY TO A USER RESIDING IN SUCH STATES.

SUCH LIMITATIONS, EXCLUSIONS AND DISCLAIMERS SHALL APPLY TO ALL CLAIMS FOR DAMAGES, WHETHER BASED IN AN ACTION OF CONTRACT, WARRANTY, STRICT LIABILITY, NEGLIGENCE, TORT, OR OTHERWISE.YOU HEREBY ACKNOWLEDGE AND AGREE THAT THESE LIMITATIONS OF LIABILITY ARE AGREED ALLOCATIONS OF RISK CONSTITUTING IN PART THE CONSIDERATION FOR LIGHTSOLVER’S SITE TO YOU, AND SUCH LIMITATIONS WILL APPLY NOTWITHSTANDING THE FAILURE OF ESSENTIAL PURPOSE OF ANY LIMITED REMEDY, AND EVEN IF LIGHTSOLVER AND/ORANY LIGHTSOLVER PARTIES HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH LIABILITIES AND/OR DAMAGES. THE FOREGOING LIMITATION OF LIABILITY SHALL APPLY TO THE FULLEST EXTENT PERMITTED BY LAW IN THE APPLICABLE JURISDICTION AND IN NO EVENT SHALL LIGHTSOLVER’S CUMULATIVE LIABILITY TO YOU EXCEED $100.

You agree to defend, indemnify and hold harmless LightSolver and any LightSolver Parties from and against any and all claims, damages, obligations, losses, liabilities, costs, debts, fines, late fees, cancellation fees and expenses (including attorney’s fees) arising directly or indirectly from: (i) your use of the Site (or any part thereof); (ii) breach of any term of these Terms by you or anyone on your behalf; (iii) any damage of any sort, whether direct, indirect, special or consequential, you may cause to any third party which relates to your use of (or inability to use) the Site; (iv) your violation of the Privacy Policy, any third party intellectual property rights, privacy rights or other rights through your use of the Site or provision of information; and (v) your violation of any applicable law or regulation.

Notwithstanding the foregoing paragraph, if you are a resident of New Jersey, you only agree to release, defend, indemnify, and hold LightSolver, and its officers, directors, employees and agents, harmless from and against any third-party claims, liabilities, damages, losses, and expenses, including reasonable legal and accounting fees, arising out of or in any way connected with your violation of these Terms.

LightSolver reserves the right to change these Terms, and any other documents incorporated by reference herein, from time to time, at its sole discretion and without any prior notice.LightSolver will notify you regarding material changes of the terms of theseTerms by notice on the Site or by sending you an e-mail regarding such changes to the e-mail address that you provided in the registration form. Such material changes will take effect seven (7) days after such notice is provided on ourSite or sent by email. Otherwise, changes to these Terms are effective upon notice being given, which may be made by posting the changes to these Terms on the Site. You are responsible for regularly reviewing these Terms for updates and modifications. Your continued use of the Site after notice of changes has been given will constitute acceptance of, and agreement to be bound by, those changes. If you do not agree, you may not access or use the Site.

To use the Site, you must be over the age of seventeen (17). We reserve the right to request proof of age at any stage so that we can verify that persons under the age of seventeen (17)are not using the Site. In the event that it comes to our knowledge that a person under the age of seventeen (17) is using the Site, we will prohibit and block such User from accessing the Site and will make all efforts to promptly delete any Personal Information (as such term is defined in our Privacy Policy with regard to such User.

These Terms do not, and shall not be construed to create any partnership, joint venture, employer-employee, agency, or franchisor-franchisee relationship between the parties hereto. Any claim relating to this Site or use of this Site will be governed by and interpreted in accordance with the laws of the State of California, UnitedStates, without reference to its conflict-of-laws principles. Any dispute arising out of or related to your use of this Site will be brought in, and you hereby consent to exclusive jurisdiction and venue in, the competent courts of the applicable court in the state of California, United States. If any provision of these Terms is found to be unlawful, void, or for any reason unenforceable, then that provision will be deemed severable from these Terms and will not affect the validity and enforceability of any remaining provision.You may not assign, sublicense or otherwise transfer any or all of your rights or obligations under these Terms without LightSolver’s prior express written consent. No waiver by either party of any breach or default hereunder will be deemed to be a waiver of any preceding or subsequent breach or default. Any heading, caption or section title contained herein is inserted only as a matter of convenience, and in noway defines or explains any section or provision hereof. These Terms are the entire terms and conditions between you and LightSolver relating to the subject matter herein and supersedes any prior or contemporaneous written or oral agreements or understandings between you and LightSolver. Notices to you may be made via email or regular mail. This Site may also provide notices of changes to theseTerms or other matters, by displaying such notices or by providing links to such notices. Without limitation, you agree that a printed version of theseTerms and of any notice given in electronic form shall be admissible in judicial or administrative proceedings based upon or relating to these Terms to the same extent and subject to the same conditions as other business documents and records originally generated and maintained in printed form.

For purposes of these Terms:

(i) the words “include,”“includes” and “including” shall be deemed to be followed by the words “without limitation”;

(ii) the word “or” is not exclusive;

(iii) the word “any” means “any and all”;

(iv) the words “herein,” “hereof,” “hereby,” “hereto” and “hereunder” refer to these Terms as a whole;

(v) the headings in these Terms are for reference only and shall not affect the interpretation of these Terms;

(vi) when a reference is made to a Section, such reference shall be to a Section of these Terms; and

(vii) unless the context requires otherwise, words using the singular or plural number also include the plural or singular number, respectively, and references to a “person” includes both individuals and entities and their permitted successors and assigns.

This Terms were written inEnglish and may be translated into other languages for your convenience. If a translated (non-English) version of these Terms conflicts in any way with theEnglish version, the provisions of the English version shall prevail.

If you have any questions or comments concerning these Terms or the Site, you are welcome to send us an email at the following address: support@lightsolver.com.

LightSolver Ltd., its parent company and its affiliates (“LightSolver”,“we”, “our” or “us”) respects the privacy of the users of its website at the address https://lightsolver.com/ (the“Site”) and is committed to the protection of the Personal Information (as defined below) that its Users share with it. We believe that you have a right to know our practices regarding the information we may collect and use when you visit or use our Site.

This Website Privacy Policy (this “Privacy Policy”) constitutes a binding and enforceable legal instrument between LightSolver and you – so please read it carefully. Capitalized terms that are used but not defined herein, as well as the terms “you” and “User,” shall have the meaning ascribed to them in our Website Terms of Use (“Terms of Use”), which incorporate the terms of this Privacy Policy by reference.

BY ENTERING, CONNECTING TO,ACCESSING AND/OR USING THE SITE, YOU AGREE TO THE TERMS AND CONDITIONS SET FORTH IN THIS PRIVACY POLICY, INCLUDING WITH RESPECT TO THE COLLECTION AND PROCESSING OF YOUR PERSONAL INFORMATION (AS DEFINED BELOW). IF YOU DISAGREE WITH ANY TERM PROVIDED HEREIN, YOU MAY NOT USE THE SITE.

a. The first type of information is non-identifiable and anonymous information (“Non-Personal Information”). We are not aware of the identity of the User from which we have collected Non-Personal Information. Non-Personal Information is any unconcealed information which is available to us while Users are using the Site. Non-Personal Information which is being gathered consists of technical and behavioral information, and may contain, among other things, the activity of the User on the Site, a User’s “click-stream”on the Site, etc.

b. The second type of information is information which identifies an individual, or may with reasonable effort identify an individual, either alone or in combination with other information (“Personal Information”). This information may identify you or be otherwise associated with you. The PersonalInformation that we gather consists of any personal details provided voluntarily by the User or on their behalf. The Personal Information required from the User while filling in the contact forms (including the “Login” feature, the “Support” options or use of the Site’s chat widget) may include the User’s full name, e-mail address, phone number, country, company, job title and ICCID (IntegratedCircuit Card Identification Number) and the User may also voluntarily provide other information in free text fields as part of a dedicated message to us.

For the avoidance of doubt, any Non-Personal Information connected or linked to any Personal Information shall be deemed Personal Information for as long as such connection or linkage exists. Under this Privacy Policy, the term “information” shall mean both Personal and Non-Personal Information.

We do not collect any PersonalInformation from you without your approval, which is obtained, inter alia, through your acceptance of the Terms of Use and this Privacy Policy.

We collect information via the following methods:

a. We automatically collect information through your use of the Site. As you navigate through and interact with our Site, we may use automatic data collection technologies (like browser cookies and flash cookies) to gather, collect and record certain information about your equipment, browsing actions, and patterns, including details of your visits to our Site and information about your computer and internet connection (such as your IP address, operating system, and browser type), either independently or through the help of third-party services, as detailed below.

b. We collect information which you provide us voluntarily and with your consent. For example, we collect Personal Information which you voluntarily provide when you fill different forms on the Site or contact us in any other way. We store the Personal Information either independently or through the help of our authorized third-party service providers, as detailed below.

c. We use third party software and services to collect information. Third parties may collect and process information such as usage analytics data in order to provide and operate the Site and improve our products and services.

a. We collect, process and use your information for the purposes described in this PrivacyPolicy, based at least on one of the following legal grounds:

i. With your consent: We ask for your consent, under this Privacy Policy, to process your information for specific purposes and you have the right to withdraw your consent at any time.

ii. When providing you with access to the Site: We collect and process your information in order to (i) provide you access to the Site; (ii) to maintain and improve our Site; (iii) to develop new services and features for our Users; (iv) and to personalize the Site in order for you to get a better user experience.

iii. Legitimate interests: We process your information for our legitimate interests while applying appropriate safeguards that protect your privacy. This means that we process your information for things like detecting, preventing, or otherwise addressing fraud, abuse, security, usability, functionality or technical issues with our services, protecting against harm to the rights, property or safety of our properties, or our users, or the public as required or permitted by law; enforcing legal claims, including investigation of potential violations of this PrivacyPolicy; in order to comply or fulfill our obligations under applicable laws, contractual requirements, legal process, subpoena or governmental request, as well as to enforce our Terms of Use.

b. Non-Personal Information and PersonalInformation are collected in order to:

i. to provide you with and to operate the Site, including for statistical and research purposes and creation of aggregated and/ or anonymous data;

ii. to develop, improve and customize the Site, the experience of other users and the offering available through the Site;

iii. to be able to contact you for the purpose of providing you with technical assistance, support, handle requests and complaints and collect feedback in connection with performance of the Site;

iv. to send you updates, notices, announcements, and additional information related to the Site

v. to be able to reply to your online queries in connection with performance of theSite;

vi. to display or send to you marketing and advertising material when you are using the Site, including in accordance with the section titled ‘Direct Marketing’ herein; and

vii. to comply with any governmental agencies’ legal requests or court orders, or with any applicable law, rule or regulation.

LightSolver may disclose Personal Information in the following cases: (a) to comply with any applicable law, regulation, legal process, subpoena or governmental request; (b) to enforce the Terms of Use (including this Privacy Policy) or any other agreements between you (or any persons affiliated with you) and us, including investigation of potential violations thereof; (c) to detect, prevent, or otherwise address fraud, security or technical issues; (d) to respond to your support requests; (e) to respond to claims that any content available on the Site violates the rights of third parties; (f) to respond to claims that contact information (e.g., name, e-mail address) of a third party has been posted or transmitted without their consent or as a form of harassment; (g) to protect the rights, property, or personal safety of LightSolver, its Users, or any other person;(h) in connection with a change in control of LightSolver, including by means of merger, acquisition or sale of all or substantially all of its assets; (i) to LightSolver’s third-party service providers that provide services to LightSolver to facilitate our operation of the Site or our services (e.g., Amazon Web Services); (j) for any other purpose disclosed by us when you provide the Personal Information; or (k)pursuant to your explicit approval prior to such disclosure. For avoidance of doubt, LightSolver may transfer and disclose Non-Personal Information to third parties in its sole discretion.

Except as otherwise stated in this Privacy Policy, we do not sell, trade, share, or rent your Personal Information collected from our services to third parties. We may however transfer, share or otherwise use anonymized, aggregated or non-personal information in our sole discretion and without the need for further approval. You expressly consent to the sharing of your Personal Information as described in this Privacy Policy.

We retain the Personal Information we collect only for as long as needed in order to provide you with our services and to comply with applicable laws and regulations. We then either delete from our systems or anonymize it without further notice to you. If for any reason you wish to request a modification to, or deletion of, your Personal Information in accordance with Section 13 of this Privacy Policy, you may do so by contacting LightSolver at support@lightsolver.com or through the Site.

However, please note that, although your Personal Information may be removed from our systems, LightSolver will retain any anonymous information contained therein or any anonymized or aggregate data derived therefrom, and such information will be owned by us and may continue to be used by us for any purpose, including the operation or improvement of our services.

To use the Site, you must be over the age of seventeen (17). Therefore, LightSolver does not knowingly collect Personal Information from persons under the age of seventeen (17) and does not wish to do so. We reserve the right to request proof of age at any stage so that we can verify that persons under the age of seventeen (17) are not using the Site.

We take a great care in implementing and maintaining the security of LightSolver’s Site and its User’s PersonalInformation. LightSolver employs industry-standard procedures and policies to ensure the safety of its Users’ Personal Information and prevent unauthorized access to or use of any such information. However, we do not and cannot guarantee that unauthorized access or use will never occur.

In order to provide and operate the Site, we use third-party software and services to collect and process the information detailed herein, and to improve our products and services. Examples include: web hosting, sending communications, analyzing data and conducting customer relationship management. These third-party service providers have access to the information needed to perform their respective functions, but may not use it for other purposes unless such data has been first anonymized. Further, they must process that information in accordance with this Privacy Policy and as permitted by applicable law.

LightSolver may use industry-standard technologies, such as “cookies” or similar technologies, which store certain information about you on your computer and allow us to enable the automatic activation or personalization of certain features, there by making your interactions with us more convenient and efficient. The cookies that we use are created per session and do not include any information about you, other than your session key (which is generally removed at the end of your session). Most browsers will allow you to easily erase cookies from your computer’s hard drive, block acceptance of cookies, or receive a warning before a cookie is stored. However, if you block or erase cookies, your online experience and our ability to provide the Services to your Advisor may be limited or degraded. We do not respond to do-not-track signals.

Information regarding theUsers will be maintained, processed and stored by us and our authorized affiliates and service providers in the United States and, as necessary, in secured cloud storage provided by our third-party service provider(s), which may include facilities located outside of the aforementioned location. You hereby accept the place of storage and the transfer of information as described above.

LightSolver welcomes all qualified candidates(“Candidates”) to apply to any of the open positions posted on our Site or otherwise (including without limitation – Facebook and LinkedIn) by sending us their contact details and resumes(“Candidate Information”). We are committed to keep CandidateInformation private and use it solely for our internal recruitment purposes(including for identifying Candidates, evaluating their applications, making hiring and employment decisions, and contacting Candidates by phone or in writing).

Please note that we may retain Candidate Information submitted to us even after the applied position has been filled or closed. This is done so we may re-consider Candidates for other positions and opportunities at LightSolver; so we may use such CandidateInformation as reference for future applications; and in case the Candidate is hired, for additional employment and business purposes related to their employment or engagement with LightSolver.

If you previously submitted your Candidate Information to LightSolver and now wish to access it, update it or have it deleted from our systems, please contact us at: support@lightsolver.com.

If the law applicable to you grants you such rights, you may ask to access, correct, or delete your Personal Information that is stored in our systems. You may also ask for our confirmation as to whether or not we process your Personal Information.

Subject to the limitations in law, you may request that we update, correct, or delete inaccurate or outdated information. You may also request that we suspend the use of anyPersonal Information whose accuracy you contest while we verify the status of that information.

Subject the limitations in law, you may also be entitled to obtain the Personal Information you directly provided us (i.e., excluding data we obtained from other sources) in a structured, commonly used, and machine-readable format and may have the right to transmit such data to another party.

If you wish to exercise any of these rights, contact us at: support@lightsolver.com. When handling these requests, we may ask for additional information to confirm your identity and your request. Please note, upon request to delete yourPersonal Information, we may retain such data, in whole or in part, to comply with any applicable rule or regulation, and/or to respond to or defend against legal proceedings.

To find out whether these rights apply to you and on any other privacy related matter, you can contact your local data protection authority if you have concerns regarding your rights under local law.

You hereby agree that we may use your contact details provided during registration or otherwise volunteered through the Site for the purpose of informing you regarding our products and services, the Site and other news which may interest you, and to send to you other marketing material about related products and services offered by LightSolver. You may withdraw your consent by sending a written notice to LightSolver by email to the following address: legal@LightSolver.io or by pressing the “Unsubscribe” button in the email.

The terms of this PrivacyPolicy will govern your interaction with us and your use of the Site and any information collected in connection therewith. LightSolver may change thisPrivacy Policy from time to time, in our sole discretion and without any notice. LightSolver will notify you regarding material changes of the terms of this Privacy Policy by notice on the Site or by sending you an e-mail regarding such changes to the e-mail address that you provided in the registration form. Such material changes will take effect seven (7) days after such notice is provided on our Site or sent by email. Otherwise, Changes to this Privacy Policy are effective as of the stated “Last Updated” date and your continued use of the Site after the “Last Updated” date will constitute your acceptance of, and agreement to be bound by, such changes. You are responsible for periodically visiting our Site and this Privacy Policy to check for any changes. IF YOU DO NOT AGREE WITH CHANGES TO THE TERMS OF THIS PRIVACY POLICY, YOU ARE OBLIGATED TO PROMPTLY NOTIFY US AND TERMINATE YOUR USE OF THE SITE.

If you have any questions (or comments) concerning this Privacy Policy, you are welcome to send us an email at the following address: support@lightsolver.com.